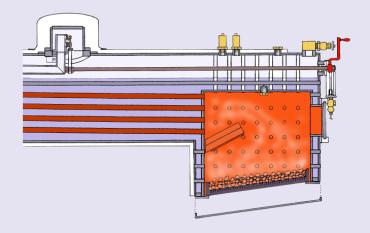

Sectional drawing of surface combustion vaporising oil burner installed in a locomotive boiler in place of conventional firebars for coal firing.

Surface Combustion Vaporising Oil Burner

Current difficulties with the supply of good quality steam coal and the attendant risks of lineside fires in the high summer from spark throwing have led us to design a development model of a new type of oil burner to enable locomotives to be capable of dual fuel operation. The new burner system enables a coal fired locomotive to be operated with the option of either conventional coal firing or oil firing using a surface combustion vaporising burner.

Such a burner would have a firebed of refractory 'coals' supported on a system of vaporising tubes. The gas oil fuel is vaporised within the tubes utilising heat absorbed from the hot refractory. The refractory acts as a catalyst at high temperatures and is heated to incandescence by the combustion of the gas oil vapour on its surface. The burner would be easily installed in the same position as firebars with an oil tank provided in the bunker space.

This arrangement would offer an oil firing system which would be kind to the boiler, by mimicking the slower thermal response characteristics of a coal fire with high radiant heat output, and provide clean combustion. Oil firing reduces crew work load and can be ideal for one man operation but in addition this system provides lower noise levels from the fire than conventional atomised oil systems which is also less fatiguing and can improve the passenger experience adjacent to the locomotive. Change-over between firing methods could be made in just a few hours and would offer flexibility to use whichever fuel suited the operating or commercial situation.